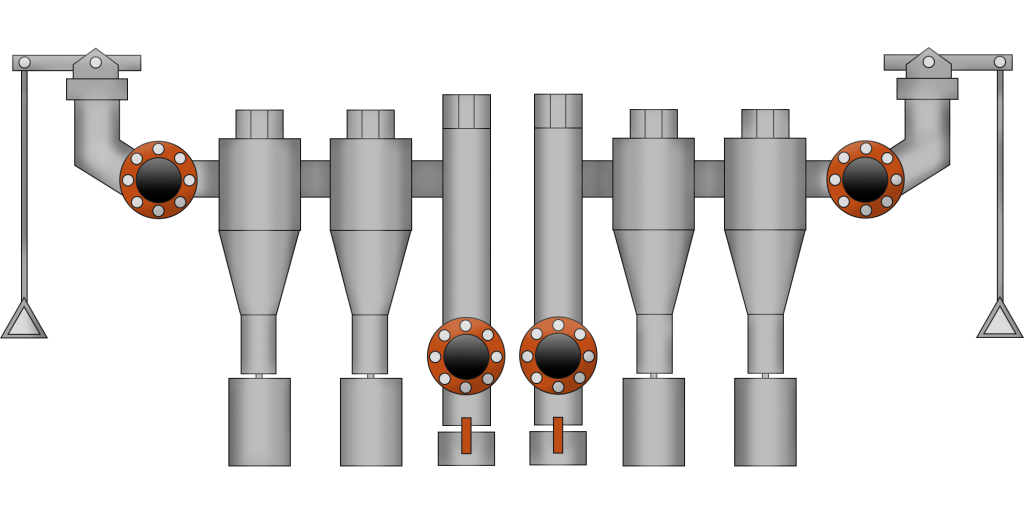

Fixed Pyrolysis Particular Separator of the RTD1600 system

A fixed pyrolysis system is a process used for the thermal decomposition of organic materials at high temperatures without oxygen. It’s critical in producing charcoal, synthetic gas (syngas), bio-oil, and other chemicals. When integrated into a charcoal retort system, this process produces charcoal and captures valuable by-products like wood tar and syngas. Let’s break down how this system works, primarily focusing on the gas cleaning system involving two cyclones and a wood tar trap and its efficiency in a charcoal retort setup.

Carbon Retort Pyrolyser System

The Retort Pyrolyser involves a stationary bed of biomass material (like wood) heated to high temperatures up to 550 degrees C. The biomass (wood) doesn’t move; heat is applied externally to the charged drum, leading to the pyrolysis of biomass (wood feedstock). This process decomposes into carbon/charcoal, volatile gases, and tar. The main product of interest in a charcoal retort is charcoal, but the volatile gases and tar can also be valuable if adequately captured and cleaned.

Gas Cleaning System

The gas mixture produced during pyrolysis, called syngas or producer gas, contains hydrogen, carbon monoxide, carbon dioxide, methane, other hydrocarbons, and contaminants like dust particles and tar droplets. It needs to be cleaned to make the gas usable, especially for energy applications. Here’s where the two cyclones and wood tar trap come into play.

Cyclones

Cyclones are used to remove particulate matter from the gas stream. Syngas is fed into the cyclone at a high velocity, creating a vortex within the cyclone chamber. Due to centrifugal forces, particles in the gas stream are thrown against the cyclone’s wall, which cools and falls to the bottom, where they can be collected. The cleaned gas exits from the cyclone’s top via a secondary internal separator chamber.

Using one or more cyclones in a series can significantly improve particulate removal efficiency. The first cyclone removes the larger particles, and the second cyclone catches finer particles, such as those that may have escaped the first one. This staged approach enhances the overall cleaning efficiency.

Wood Tar and wood vinegar Traps

After passing through the first cyclone, the gas still contains volatile tars that can condense to wood vinegar and wood tar. The traps at the base of each cyclone are designed to capture these tars. They can work based on several principles, such as cooling the gas to condense the tars and physically trapping them to remove tar droplets from the gas stream.

Efficiency in a Charcoal Retort

Integrating this gas cleaning system in a charcoal retort setup significantly improves charcoal production’s overall efficiency and environmental footprint. It allows for the following:

- Capture of Valuable By-products, such as wood vinegar and wood coal tar, which can be used in various industrial applications, and clean syngas can power the retort.

- Reduction of Emissions: Cleaning the syngas reduces the emission of particulates and hazardous compounds, making the process more environmentally friendly.

- Improved Charcoal Quality: By efficiently removing by-products from the retort, the quality of the charcoal can be enhanced, as it minimises the contamination of charcoal with tar.

Using one or more cyclones followed by wood tar traps, the Pyrolyser system with a charcoal retort setup efficiently cleans syngas. It captures valuable by-products like wood vinegar or tar. This makes the process more economically viable by utilising all pyrolysis products and reduces the environmental impact by capturing potentially harmful particulates and tars. The effectiveness of this setup in a charcoal production context demonstrates a sustainable approach to biomass utilisation, aligning with modern energy and our environmental goals.

Pyrolysis Retorts

Find Out More

If you would like more information, provide your details below and we’ll get back to you ASAP!